New Breed of Safety Logic Solver Enhances Efficiency and Safety for Distillation Columns

Temperature stratification in distillation columns poses significant challenges to process efficiency and safety. Variations in temperature along the height of the column can upset the balance between the liquid and vapor phases, resulting in less effective separation and lower-quality output. Furthermore, temperature variations might result in isolated hotspots or cold areas, raising the possibility of thermal strains, equipment malfunctions, and even possible safety risks like thermal runaway or column flooding.

Temperature stratification in distillation columns poses significant challenges to process efficiency and safety. Variations in temperature along the height of the column can upset the balance between the liquid and vapor phases, resulting in less effective separation and lower-quality output. Furthermore, temperature variations might result in isolated hotspots or cold areas, raising the possibility of thermal strains, equipment malfunctions, and even possible safety risks like thermal runaway or column flooding.

Introduction

Distillation columns are critical components in various industries, but temperature stratification can impact their efficiency and safety. To keep the distillation process operating at peak efficiency and protect workers, machinery, and product integrity, temperature stratification must be monitored and moderated. When safety is involved, temperature monitoring across various zones is often done by safety PLCs to detect and mitigate stratification early on as most single logic solvers cannot handle multiple inputs and other required shutdown decision making. Although effective, safety PLCs typically come with a high price tag and programming complexity, which begs the question of “Is there a more efficient and cost-effective solution available?”. To bridge the gap between cost and efficiency, Moore Industries introduces a new breed of safety logic solving with the SLA Multiloop Logic Solver.

Understanding Temperature Stratification

Temperature stratification within distillation columns is a multifaceted phenomenon driven by a combination of thermal, fluid dynamic, and compositional factors. At its core, temperature stratification denotes the uneven distribution of temperature gradients along the vertical axis of the distillation column. This thermal imbalance arises from various sources, including the localized application of heat at the column’s base, irregular fluid flow patterns, and variations in feed composition. These disparities in temperature distribution can engender a cascade of adverse effects, ranging from diminished separation efficiency and compromised product quality to heightened safety risks within the distillation process.

Effective monitoring of temperature across multiple zones within the distillation column is paramount for detecting and mitigating the ramifications of temperature stratification. Utilizing a network of strategically positioned temperature sensors enables real-time monitoring of temperature profiles along the column’s height, facilitating early detection of stratification-induced deviations. Such comprehensive monitoring allows for the timely implementation of targeted control strategies aimed at restoring thermal equilibrium within the column. By employing robust monitoring protocols and responsive intervention measures, operators can safeguard distillation processes against the deleterious effects of temperature stratification, therefore optimizing efficiency, product quality, and operational safety. Choosing a logic solver that inherently achieves all of the aforementioned operation and safety requirements was once limited to larger safety PLC systems. Today, more dynamic logic solvers like the SLA Multiloop Logic Solver, offer safety and application capabilities at a fraction of the cost that were once resigned solely to safety PLCs.

Key Logic Solver Attributes Required For a Multi-zone Temperature Distillation Column Application

Key Logic Solver Attributes Required For a Multi-zone Temperature Distillation Column Application

- Multiple Inputs: Temperature stratification control and/or monitoring will require reading multiple temperature signals positioned throughout the column.

- Equation/Logic Capability: Analyzing the column’s section actual, average or absolute temperature is required for product quality, column operational efficiency and safety. Performing logic on multiple temperature inputs or zones is a must.

- Straight Forward Voting Logic Capability: Whether operational efficiency, quality, or safety shutdown is required, multi-zone alerts and/or alarming that have dependency amongst multiple sections of the column (voting schemes) are imperative.

- Simple and License Free Programming: Ideally no custom or licensed software would be required to configure or maintain the logic solver for the application.

SLA as the Logic Solver in a Distillation Column Temperature Monitoring Application

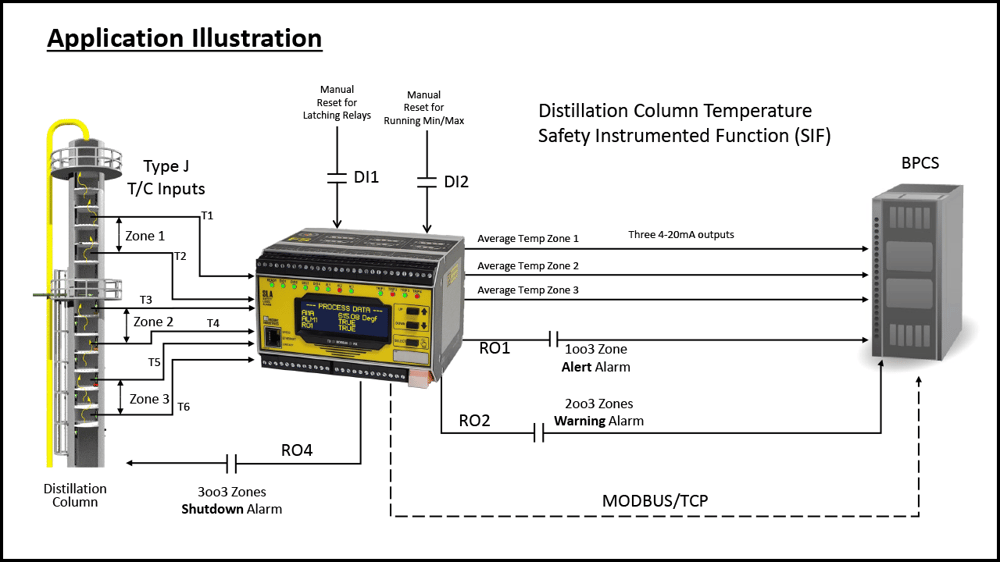

Temperature stratification is normal in distillation columns. However, in some chemical or refinery processes, too much temperature differential between layers within the column can yield poor quality product or create a dangerous condition that could lead to a column rupture or explosion. In this application, Zone 3’s ideal temperature range is around 250 degC, Zone 2’s ideal temperature range is around 200 degC, and Zone 1’s ideal temperature range is around 150 degC. Closely monitoring these temperatures, providing alarming, and possible shutdown of the process is crucial.

The SLA can help mitigate this situation by accepting up to six temperature inputs, in this case type J thermocouples, and performing an absolute differential calculation between two closely mounted temperature elements in each zone. The SLA can implement up to 16 alarms based on any input, equation, or combination of inputs/equations.

This application requires three separate alarms, one for each zone, where each alarm is configured to activate if more than a 25 degC temperature differential exists between each zone’s lower and upper temperature points. The temperature differential for each zone is calculated with an absolute differential equation via the SLA’s Internal Variable/Equation Editor feature. Three of the SLA relay outputs will be driven by an alarm voting strategy. Relay Output 1 will activate an alert if any of the three zones experience an alarm (1oo3 voting). Relay Output 2 will issue a warning if any two of the zones are in alarm (2oo3 voting), and Relay Output 4 will initiate a shutdown of the distillation column if all three zone alarms are active (3oo3 voting) or if there is an SLA device fault.

A contact closure wired to the SLA’s Discrete Input 1 is used to release Relay Outputs 1, 2 & 4, all latching relays, once an alarm voting condition(s) has become inactive. Discrete Input 2 will be utilized to reset a running min/max function that will capture each zone’s maximum temperature, since last reset.

A BPCS (Basic Process Control System) monitors each zone’s average temperature via the SLA’s three analog outputs. All inputs, outputs, alarms, faults, and various other parameters from the SLA are transmitted via MODBUS/TCP over Ethernet to the BPCS. Additionally, the SLA’s event logger will be enabled and configured to monitor and store all diagnostic and alert information for the analog inputs and relay outputs. This event log file can then be downloaded from the SLA as a .csv file for viewing, analysis, and archiving.

Efficacy of the Multiloop Logic Solver

The SLA Multiloop Logic Solver was designed to streamline safety and efficiency within safety applications such as the example application in this whitepaper. Earlier standalone logic solvers made available to the marketplace had limited input and output capabilities. The SLA now introduces a new breed of logic solver that has multiloop capabilities with up to 17 onboard I/O points, no expansion cards required. This makes the SLA an ideal and innovative choice for providing safety or control by multiple thermocouple inputs on a distillation column.

Logic capability is central to any application like this where multiple inputs need to be analyzed or massaged for product quality or higher-level decision-making. Unlike traditional Safety PLCs, the SLA’s Equation/Expression Editor is a powerful but easy-to- use tool, empowering end-users to seamlessly execute simple or complex math functions without the need for specialized programming. This innovative approach not only simplifies setup and programming but also ensures safety requirements can be met without overburdensome programming. With the Equation/Expression Editor on the SLA you can create monitoring, alarming, and control schemes that involve simple to complex equations using timers, running min/max functions, prebuilt analog and discrete logic functions, and more.

Often safety is applied with layers. Before a full-blown shutdown takes place, there are various phases that a process or vessel reaches when mitigating steps can be taken to avoid dire or unwanted consequences. Voting logic is typically incorporated to look for more than one or two variables that have been breached before countermeasures are taken. The SLA includes easy to configure built-in logic voting capability that avoids complex ladder logic or other programming complexities. Once any of the SLA’s 16 alarms have been configured, relay outputs can then be driven with any desired voting logic, such as 1oo2, 2oo3, or even 5oo10, by selecting check boxes within a simple FDT (Field Device Technology) application.

For this distillation column application, multiple inputs, outputs, logic and voting functions were all necessary requirements. While the application required some dependencies on equations and voting logic, to configure the SLA logic solver no custom or complex software was required. The SLA is configured with FDT/DTM technology. An industry-leading, end user license-free, and ubiquitous open platform for programming field devices. This not only makes the programming user-friendly but also alleviates the initial and long-term ownership cost of the logic solver.

Conclusion

In conclusion, temperature stratification in distillation columns presents significant challenges to process efficiency and safety, requiring proactive monitoring and intervention measures. Moore Industries’ SLA Multiloop Logic Solver offers a comprehensive solution tailored to address these challenges effectively. By simultaneously monitoring temperature across three zones, providing alarming capabilities, and offering shutdown functionality, the SLA enables operators to detect and identify temperature stratification promptly.

Through its advanced features, such as the Equation Editor, Alarm Voting Architectures, Simplicity to Program with FDT/DTM Software, and Up to six Inputs, the SLA empowers operators to maintain optimal temperature distribution within the distillation column, thereby enhancing separation efficiency, product quality, and operational safety. Moreover, the SLA Multiloop Logic Solver’s cost-effectiveness and scalability make it a viable solution for both new installations and retrofitting existing systems, ultimately leading to cost savings, enhanced productivity, and optimal process performance when compared to traditional safety PLCs.

Download a copy of the White Paper